Description

2014 Larox PF96 M48 Automatic Filter, Filtration Area 96 m2 (1033 ft2), New Unused Surplus. Equip yourself with the gold standard.

Manufacture & Design

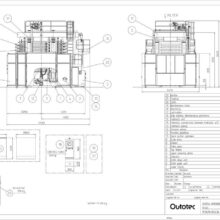

- Model #: PF96/96 M48 2 60

- Filter Type: PF

- Filtration Area: 96 square meters (1033 square feet)

- Filter Series: M48

- Construction Material: 2 (AISI 316L all metal parts in contact with slurry)

- Chamber Height: 60 mm

- Serial #: 1125

- Year: 2014

- Max Pressure: 16 Bar

- Voltage: 575 Volt

Components & Inclusions

- (16) Filter Plates

- 1500 x 4010 mm

- 59″ x 158″

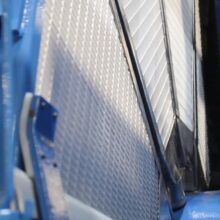

- Filter Cloth

- 1.7 x 95.5 m

- 5.5 ft. x 313 ft.

- Larox 800 Hydraulic Unit

- 110 KW Hydraulic Unit Motor

- 15 KW Hydraulic Unit Motor

- 3 KW Oil Cooler Motor

- 3 KW Oil Heater

- Lubrication

- Control Panel

Manufacturer Brochure Information

2014 Larox PF96 M48 Automatic Filter Operation:

The machine is intended for indoor professional automatic use in the mining and chemical process industries. It is an automatic operating pressure filter for efficient solid/liquid-separation. The machine can be operated remotely from a control room or locally from the control panel. The main operating stages of the PF filter include filtering, diaphragm pressing, cake washing and compressed air drying.

- Filtration:

When the filter plate pack has been closed, slurry is pumped into the filter and fed simultaneously into each filter chamber through the distribution pipes. Filtrate flows through the cloth into the filtrate collection area, then out through the discharge pipe. The filtered material is collected on the cloth surface and forms the filter cake. - Pressing:

Pressing air flows in behind the rubber diaphragm. The diaphragm presses the cake against the cloth surface, thus pressing the filtrate from the cake through the cloth. - Drying:

The final drying of the cake is accomplished with compressed air. The air which enters through the distribution pipe fills the filter chamber, raises the diaphragm and forces the pressing air above the diaphragm out of the filter. The air flow through the cake reduces its moisture content to the optimum and, at the same time, empties the filtrate chamber. - Cake Discharge:

When the air drying has been completed, the plate pack is opened and the cloth moving mechanism started. The filter cake on the cloth is discharged from both sides of the filter.