Description

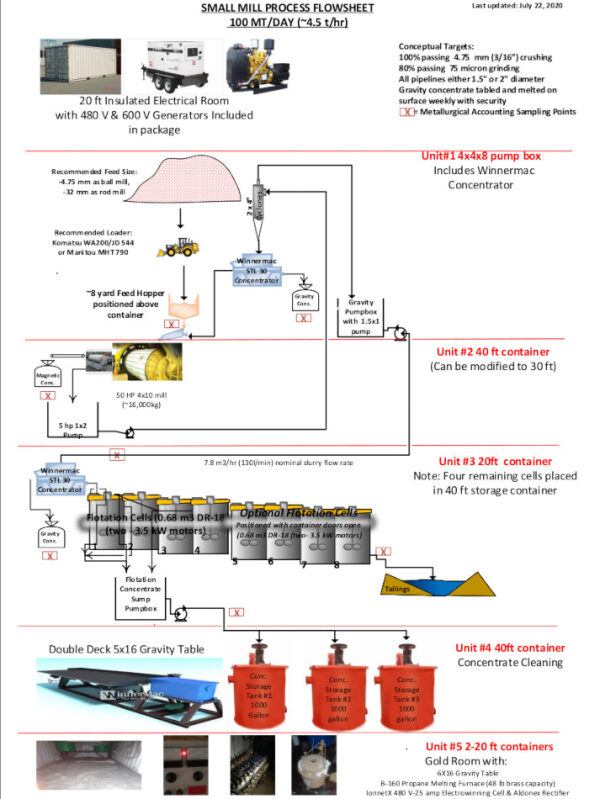

100 TPD Modular Gold Tailings Plant, 4′ x 10′ ball mill, flotation cells, gold concentrator, & concentrating table. Equip yourself with the gold standard.

History

- All equipment was energized and rotated in September 2019 prior to disassembly

- Mineral processing equipment is stored in three 40′ containers and one 20′ container

- Gold concentration & refining equipment reassembled to operate on 480 Volt

Manufacture & Design

- Designed as 5 modules

- Conceptual targets:

- 100% passing 4.75 mm (3/16″) crushing

- 80% passing 75 micron grinding

- All pipelines either 1.5″ or 2″ diameter

Module #1 – Gold Concentrator (on pump box)

- Winnermac STL30 centrifugal concentrator

- Capacity: 2-8 TPH

- Particle size: 0-4 mm

- Positioned on the pump box

- 3.7 KW Siemens motor, 208/480 Volt

- Two compartment pump box

- 4′ x 8′ x 4′ high

- First compartment for concentrator feed

- Second compartment set up to hold 1 T super sacks for holding gravity concentrates

- (2) – 4″ Cyclones

- 1.5″ x 1″ Pump

- Spare Winnermac STL30 centrifugal concentrator, stored in 20′ container

Module #2 – Ball Mill (40′ container + 20′ container)

- 2017 Winnermac 4′ x 10′ ball mill — UNUSED

- 1200 mm x 3000 mm

- Steel liners

- Mill speed: 36 RPM

- Ball load: 3.5 T

- Max feed size: 25 mm

- Capacity: 5 TPH

- 37 KW (50 HP)

- Gears professionally installed & laser aligned

- Stored in dedicated 40′ container (spray foam insulated)

- 2′ x 4′ Winnermac magnetic drum separator

- 20 T feed bin can be positioned directly above feed chute

- Field disconnects installed in mill

- Benshaw speed controller installed in separate insulated 20′ container

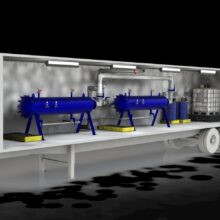

Module #3 – Flotation (20′ container)

- (8) – Winnermac flotation cells

- 18 cu-ft. per cell

- Denver style flotation

- Double drives with 3.3 KW motors

- Designed to fit in a 20′ container on the assumption the last four cells slide out when operating

Module #4 – Concentrate Cleaning (40′ container)

- (3) – 1000 Gallon agitated concentrate storage tanks

- 6′ x 15′ Winnermac double deck gold concentrating table

Module #5 – Gold Refining (2 – 20′ containers)

- 6′ x 15′ Winnermac double deck gold concentrating table

- PMPC IonnetX electrowinning cell

- 25 KW Aldonex rectifier

- Aldonex air cooled power supply

- 1000 ADC, 0-12 VDC

- 2016 MIFCO (McEnglevan) B160 propane gold smelting furnace

- Requires 300 lb. propane supply for 425,000 BTU

Additional Equipment

- Unused 3′ x 8′ Rotary trommel screen with 1/4″ mesh

- Unused Cyclone dust collector

- Unused 8″ x 6′ Winnermac sand screw classifier

- Unused 1″ Finish Thompson chemical pump

- Topaz oxygen concentrator

- Fluid exponents – canister style carbon water filter

- (2) – 20 T feed hoppers

- 110 Gallon Roth waste oil tank

- 4″ Vezin sampler, pneumatic, rotary style, stainless steel

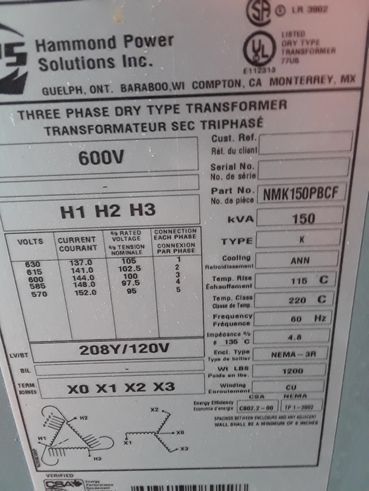

- 100 KW, 600 Volt Cummins genset

- Vibratory feeder

- Unused 18″ x 26′ Conveyors