Description

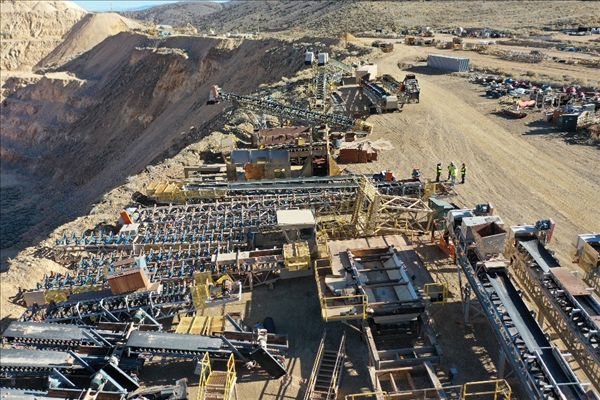

Crushing Plant for Heap Leach up to 20k TPD including feeders, screens, conveyors, & stackers. Equip yourself with the gold standard.

History

The semi-portable modular crushing plant was feeding a heap leach operation up to 20,000 TPD.

Components & Inclusions

- Crushers

- Feeders

- Screens

- Conveyors

- Tanks & Bins

- Pump

- Electrical

- Buildings

Crushers

- 32″ x 44″ Telsmith Hydra primary jaw crusher

- Spare 32″ x 44″ Telsmith jaw crusher

- FLSmidth Raptor XL 500 secondary cone crusher

- Excel Raptor XL 400 tertiary cone crusher

- (2) – FLSmidth Raptor XL 400 tertiary cone crushers

Feeders

- 36″ x 21′ Actech AC-36-FDR primary apron feeder

- 60″ x 24′ KPI-JCI Kolberg Pioneer scalping grizzly

- 48″ x 20′ Telsmith vibrating grizzly feeder

- Single deck horizontal, W/280HF

- Tertiary distribution feeders

- Tertiary crusher feeders

Screens

- 8′ x 20′ KPI-JCI Kolberg Pioneer double deck secondary screen

- 7′ x 20′ Telsmith double deck tertiary screen

Conveyors

- 36″ x 60′ Conveyor with undercarriage for jaw crusher discharge

- (18) – 42″ wide Conveyors for screen feed & undersize

- Most manufactured by McCord Conveyor Systems

- Various 48″ & 60″ secondary & tertiary conveyors

- 36″ x 150′ KPI-JCI Kolberg Pioneer series 33 SuperStacker

- Lime screw conveyor

Tanks & Bins

- (4) – Crusher feed bins

- Lime silo

- Water tank with pump for dust control

Electrical

- Control panel & junction box

- Transformers

- Hydraulic & lubrication packages

- Allen Bradley Centerline 2100 containerized MCC

Buildings

- (2) – Electrical buildings

- Control room

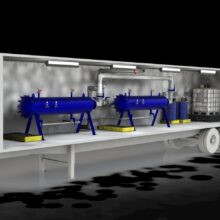

- Water treatment building