Description

3″ Goulds 46SV Multistage Vertical Pumps, 40 HP, 3500 RPM, 225 GPM, Stainless Steel, 6 Stages. Equip yourself with the gold standard.

Manufacture & Design

- Goulds Pumps, ITT

- G&L Series SSV (Stainless Steel Vertical)

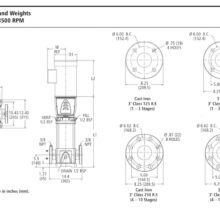

- Model #: 46SVBF22R3TA

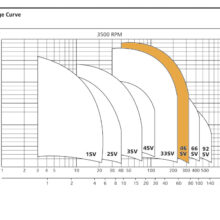

- Nominal Flow: 225 GPM

- Max. Head: 1210 ft.

- Max. Working Pressure: 580 PSIG

- Construction

- 316L Stainless Steel Liquid End

- Cast Iron Castings

- In-line ANSI Flanges

- Stages: 6

- Reduced Impellers: 2

- Speed & Frequency

- 3500 RPM

- 60 Hz, 3 Phase

- Power: 40 HP

- Voltage: 230/460 Volt

- Motor: TEFC

- Mechanical Seal

- Rotary: Silicon Carbide

- Stationary: Carbon

- Elastomers: Viton

Components & Inclusions

- (3) – New Unused Pumps

- Original Factory Crates & Packaging

- 40 HP Baldor Motors

- 230/460 Volt

- 3520 RPM

Manufacturer Brochure Information

- The 3″ Goulds 46SV Multistage Vertical Pumps are non-self priming vertical multistage pumps coupled to a standard motor. The liquid end, located between the upper cover and the pump casing, is held in place by tie rods.

- Vertical multistage centrifugal pump with impellers, diffusers and outer sleeve made entirely of stainless steel, and with pump casing and motor adapter made of cast iron.

- Seal housing chamber designed to prevent the accumulation of air in the critical area next to the mechanical seal.

- Pump body fitted with taps for installing pressure gauges on both suction and delivery flanges.

- In-line ports with ANSI flanges that can be coupled to counter-flanges, in compliance with ANSI raised face.