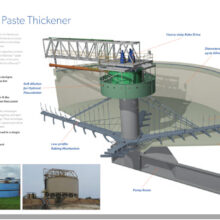

Description

35m (115′) Westech Paste Thickener, Commissioned But Not Put Into Production, Drawings Available. Equip yourself with the gold standard.

Manufacture & Design

- WesTech HiDensity™ Thickener

- Paste Thickener PT235

- Diameter: 35 m (114′ 10″)

- Sidewall Depth: 8 m (26′ 3″)

- Process Design:

- Dry Feed Tonnage (Day): 221 STPH

- Dry Feed Tonnage (Night): 171 STPH

- Feed % Solids: 12%

- Solids SG: ~2

- Underflow % Solids: 40% – 50%

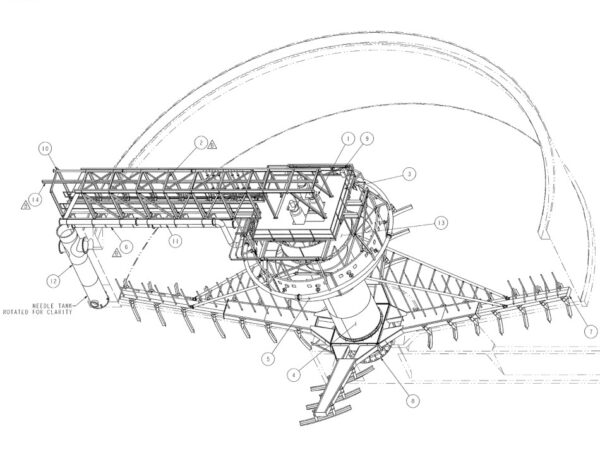

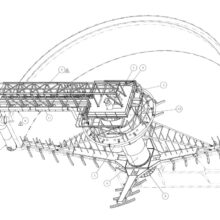

Components & Inclusions

- Tank

- Anchor Channel

- 35m x 8m

- 36″ Sch XS Overflow Nozzle

- 36″ Manway Door with a Davit Arm

- Drive Unit with Torque Control Device

- 100″ Drive Unit

- Duty Rated Torque: 2,000,000 Ft-lbs.

- Drive Control Panel

- Torque Tube

- Rakes

- Steel Rake Arms

- With Rake Blades, Pickets, & Posts

- Feed Pipe, Steel

- Diameter: 20″

- Feedwell, Steel

- Diameter: 29′ 6″

- Side Water Depth: 6′ 7″

- Column, Steel

- Diameter: 8′ 2-7/16″

- Flocculant Pipe, Steel

- 4″ 150# RFSO

- Dilution Pipe, Steel

- 14″ 150# RFSO

- Needle Tank, Steel

- Evenflo, Steel

- Rubber Lined Interior

- Walkway with Stairs & Handrail

- Monorail, 3500 Lb. Capacity

- Electrical Room (Container)

Notes & History

- Thickener was commissioned but never put into production

- Construction drawings dated 2014

- Currently installed but will be dismantled and loaded on trucks when sold

- Factory drawings available and included with purchase

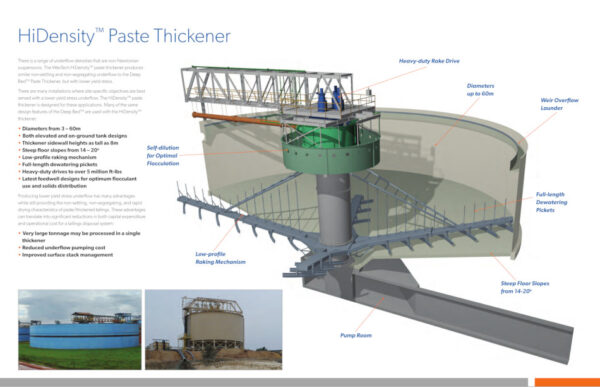

Manufacturer Brochure Information

There is a range of underflow densities that are non-Newtonian suspensions. The WesTech HiDensity™ paste thickener produces non-settling and non-segregating underflow with low yield stress. There are many installations where site-specific objectives are best served with a lower yield stress underflow. The HiDensityTM paste thickener is designed for these applications.

Producing lower yield stress underflow has many advantages while still providing the non-settling, non-segregating, and rapid drying characteristics of paste/thickened tailings. These advantages can translate into significant reductions in both capital expenditure and operational cost for a tailings disposal system:

- Very large tonnage may be processed in a single thickener

- Reduced underflow pumping cost

- Improved surface stack management